Containers come in various forms based on cargo needs and transport conditions:

- The most common is the Dry Storage Container, used for general goods.

- Flat Rack and Open Top Containers handle oversized or tall cargo.

- Refrigerated (Reefer) and Insulated Containers protect temperature-sensitive goods, while Tank Containers carry liquids and gases.

- Storage Containers serve static uses like site offices or pop-up shops.

- Newer types include Smart IoT Containers for real-time tracking, High Cube for extra space, and Eco-Material Containers designed for sustainability.

In 2025, the focus is shifting toward smarter, greener, and more modular container systems.

You have a long weekend ahead. So you plan a quick trip and pack for it. A few months later, the sun is shining bright and your kids are pestering you for a summer trip. This time, you pack big suitcases for your long vacation. Even at home, the requirements for packing changes according to needs right?

The products in your home have a similar global journey. For each item to reach you safely and effectively, the appropriate "travel bag" is required. Take a look around you. The coffee beans in your mug, the chair you're sitting in, and the device you're using to read this. It's highly likely that at least one of these things came in a corrugated steel box for a part of its way to you.

However, not every container is the same. The kind of container a product travels or is stored in depends on its particular requirements. Let's analyse the primary container types you'll come across in this article.

The Container Family Tree - Types of Containers

Here’s a quick overview of the different types of containers and their primary roles:

|

Container Type

|

Key Features

|

Common Uses

|

|

Dry Storage Container

|

Standardized size, durable steel construction, weatherproof.

|

It is the common workhorse that is used for general dry goods like electronics, clothes, and packaged food.

|

|

Flat Rack Container

|

Removable sides, open-top option, reinforced base.

|

Used for heavy or oversized cargo like machinery, timber, or industrial parts.

|

|

Open Top Container

|

Removable tarpaulin roof instead of a solid top.

|

Used for loading from the top for tall items or goods that don't fit through a standard door.

|

|

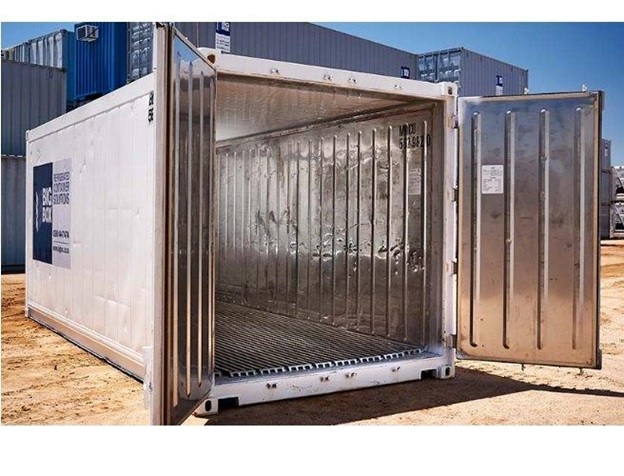

Refrigerated Container (Reefer)

|

Integrated refrigeration unit, insulated walls.

|

Best for perishable goods like frozen food, pharmaceuticals, fresh produce, and certain chemicals.

|

|

Tank Container

|

Cylindrical steel tank mounted within a frame.

|

Used to transport liquids, gases, and powders like fuel, chemicals, and food-grade liquids.

|

|

Insulated Container

|

Thermal insulation without active cooling.

|

Best for protecting goods from rapid temperature changes, but not for long-term refrigeration.

|

|

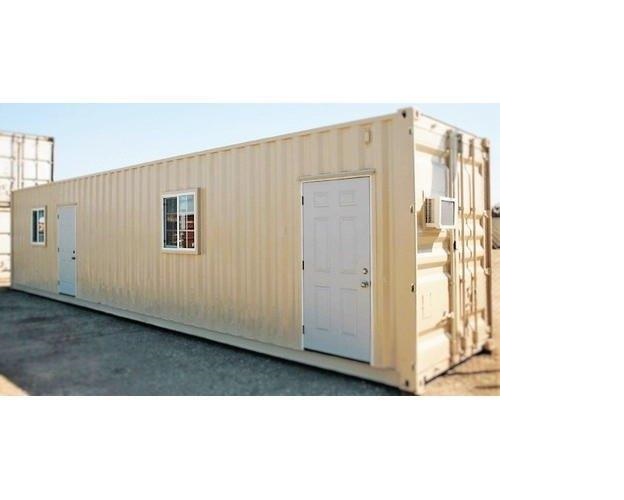

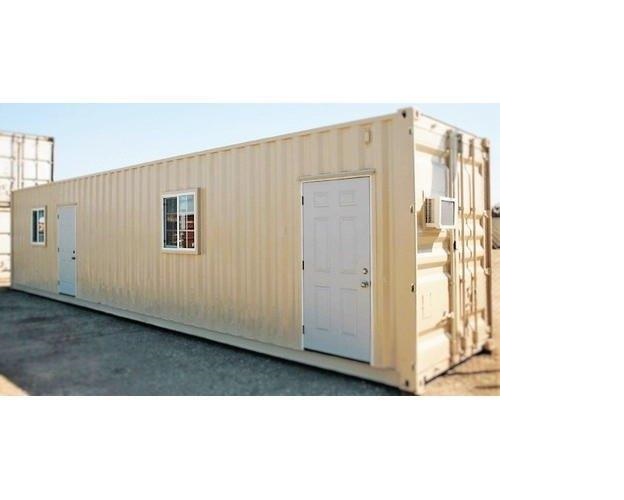

Storage Container

|

Similar to shipping containers, often modified with doors/windows.

|

Well-suited for on-site secure storage, pop-up shops, and modular site offices.

|

A Deeper Dive into Each Container

Now that we've seen the lineup, let's get to know each one a little better.

-

Dry Storage Containers

This is the box you picture when you think of a container. Built from robust steel and coming in standard 20-foot and 40-foot lengths, they are perfectly designed to stack high on massive ships, trains, and trucks. Their sealed, weatherproof nature makes them ideal for the vast majority of the world's dry cargo. If it’s not temperature-sensitive, oddly shaped, or liquid, it’s probably in one of these.

Source: IndiaMART

-

Flat Rack Container

Some things just won't fit in a standard box. That's where the flat rack comes in. It has a solid, reinforced floor but the sides are collapsible or removable. This allows for cargo that is excessively wide, heavy, or awkwardly shaped. They are essential for shipping things like construction vehicles, large pipes, or heavy machinery. You can also find open-top versions for loading from above.

Source: IndiaMART

-

Open Top Container

Similar to the flat rack, the open-top container solves a different loading problem. It has standard side walls but the roof is a removable, waterproof tarpaulin sheet. This is a game-changer for cargo that is too tall for a standard door or is best loaded by a crane from above. Think of items like large industrial equipment, sheets of glass, or bulky manufacturing components.

Source: IndiaMART

-

Refrigerated Container (Reefer)

This is the container that brings you fresh berries in winter and ensures your medicine remains potent. A reefer is essentially a massive, portable refrigerator. It has a sophisticated climate control unit that can maintain a specific temperature, and sometimes even control humidity, for the entire journey. Without these, global trade in perishable food and sensitive pharmaceuticals would look very different.

Source: IndiaMART

-

Tank Container

When your cargo flows, you need a tank. A tank container is a large, stainless steel tank securely housed within a standard container frame. This brilliant design allows liquids, gases, and powders to be handled with the same efficiency as boxed cargo. They transport everything from wine and cooking oil to hazardous chemicals and fuels, with the tank interior tailored to prevent contamination or reaction.

Source: IndiaMART

-

Storage Container

Once a shipping container has finished its life at sea, it often gets a second act. These retired boxes are incredibly versatile for static storage. You see them on construction sites, in industrial yards, and even converted into trendy pop-up cafes. They provide a secure, durable, and modular space. Many are modified with extra doors, windows, or ventilation to suit their new purpose.

Source: IndiaMART

-

The High Cube Container

An extra foot of height of your standard 40-foot container is the High Cube. It’s not a dramatic change, but in the world of logistics, that extra vertical space is pure gold. It’s perfect for voluminous but lightweight cargo. Think furniture, large appliances, or rolls of packaging materials. You can simply pack more in, making transportation more efficient. They are easily spotted by their taller profile.

Source: IndiaMART

-

The Mini / Cut-Down / Duo-Con

Not everything needs a 40-foot behemoth. For smaller loads, last-mile deliveries, or tight urban spaces, smaller containers are the answer. The Mini or Cut-Down is essentially a half-length or even smaller version of a standard box. The Duo-Con system takes it further, often featuring a collapsible design that saves space on return journeys. They bring the efficiency of containerization to smaller-scale logistics.

Source: IndiaMART

-

Insulated / Thermal / Controlled Atmosphere Containers

While a Reefer actively cools, an insulated or thermal container is all about passive protection. Its thick, insulated walls slow down temperature change, protecting goods from external heat or cold for a period. But the innovation goes further. Some are Controlled Atmosphere (CA) containers. These not only control temperature but also actively manage the levels of oxygen, carbon dioxide, and nitrogen inside. This technology slows down the ripening of fruits like bananas and apples, allowing them to travel across oceans and still arrive perfectly fresh.

Source: IndiaMART

-

Tunnel / Double-Door / Side Access Containers

A standard container has doors at one end. But what if you could load and unload from both ends? That’s the tunnel container. Or what if you need access from the side? These designs are all about improving workflow. Forklifts can drive straight through a tunnel container. Long, awkward items like pipes or lumber can be easily loaded through side doors. They turn a static box into a dynamic part of the loading process.

Source: IndiaMART

-

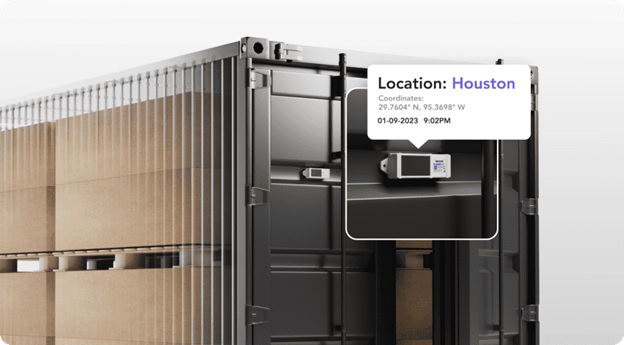

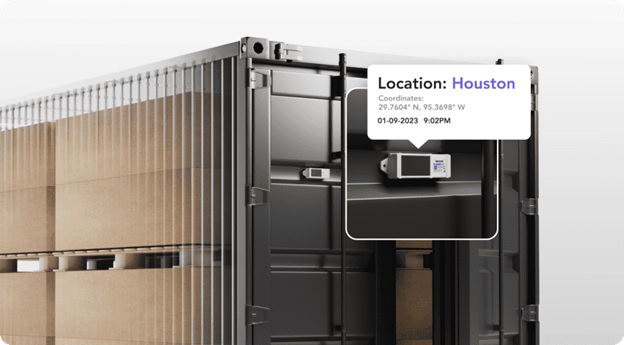

Smart / IoT / Sensor-Equipped Containers

This is a game-changer. Imagine a container that can talk. Smart containers are equipped with IoT (Internet of Things) sensors that track its condition in real-time. We’re not just talking about location. These sensors can monitor internal temperature, humidity, sudden impacts, and even if the door has been opened. This gives shippers and companies like SMC Insurance an unprecedented level of visibility. If a reefer unit fails, an alert can be sent instantly. If a container is dropped, we know. This real-time data helps prevent losses and creates a transparent chain of custody.

Source: Nexxiot

-

Sustainable / Eco-Material Containers

The future is green, and containers are joining the movement. While still largely steel, innovation is happening. This includes using COR-TEN steel (which forms a protective rust-like layer, reducing the need for paint) and exploring lightweight composite materials that reduce fuel consumption. The focus is on creating more durable, energy-efficient, and ultimately recyclable units, reducing the environmental footprint of every shipment.

Source: Greenbox Containers

How To Choose The Right Containers For Your Business Needs?

Here’s your 5-Step checklist for container selection:

➔ What is the Physical Nature of Your Cargo?

This is always the starting point. The "what" defines the "how."

- Is it Dry, Liquid, or Gas?

Dry goods like electronics or textiles are happy in a standard container. But liquids, fuels, or food-grade oils demand a secure ISO Tank. Gases require specialized, pressurized tank containers.

- What are its Dimensions and Weight?

If your cargo is tall and bulky, an Open-Top or High Cube container might be necessary. Is it excessively heavy or wide? A Flat Rack is your best choice, designed for outsized items like machinery or construction equipment.

➔ What is the Journey's Environmental Impact?

Your goods don't travel in a vacuum. They face heat, cold, humidity, and rough handling.

- Is it Temperature-Sensitive?

If your goods are perishable like fresh fruit, frozen food, or certain pharmaceuticals, a Refrigerated (Reefer) container is the best. It’s a portable refrigerator that maintains a precise temperature from origin to destination. If your goods just need protection from extreme temperature swings but not active cooling, an Insulated or Thermal container could be sufficient.

- Is it Fragile or Sensitive to Atmosphere?

For the most delicate cargo, like certain produce that ripens with gas, a Controlled Atmosphere (CA) container can be a lifesaver, actively managing the internal air composition to preserve freshness.

➔ How Will You Load and Unload?

The loading process can dictate the container type.

- Will you load from the top, side, or end?

If you're using a crane to lower in heavy equipment, an Open-Top is essential. If you need forklift access from both ends for speed, a Tunnel container is your answer. For long, awkward items like pipes or timber, Side Access doors would be a good choice.

- What are the access limitations at the destination?

A small urban store might not be able to handle a 40-foot container. In that case, a Mini or Cut-Down container could be the perfect solution for last-mile delivery.

➔ How Long is the Journey, and What is the Value?

The stakes of your shipment should influence your choice.

- Is this a short hop or a multi-week ocean voyage?

The longer the journey, the more critical the right container becomes. A cross-ocean trip exposes your goods to more potential humidity, salt air, and motion.

- What is the financial value of the cargo?

For high-value goods, the extra cost of a Smart Container equipped with IoT sensors can be a wise investment. Real-time tracking of location, door openings, and impacts provides peace of mind and valuable data for you and your insurance partner.

➔ Is it for Shipping or Storage?

Finally, consider the end goal. A container for a one-way sea voyage is built for the rigors of stacking and constant movement. A Storage Container for your business site might be a retired shipping unit, often modified with extra doors or windows. The requirements for durability and security can differ.

Future Trends and What is New in 2025

2025 is the year smart systems, modular reuse, green rules, larger rail/sea units, and automation harden into policy and large projects. The shift is evolutionary not revolutionary.

- IoT & AI Monitoring

Ports, terminals and logistics operators are adding sensors, digital twins and AI analytics to spot faults before they escalate, schedule repairs, and cut delays. NIST and industry projects name predictive maintenance as a core IoT use case. Field pilots and academic studies report successful predictive systems at container terminals.

- Modularity & Reuse

Container conversion continues to scale as private projects and markets grow for offices, clinics, retail and student housing. Governments and developers still rely mainly on standard ISO sizes, but reuse markets and conversion supply chains are expanding rapidly.

- Sustainability Push

National guidelines and port programs now require or encourage emissions cuts, onshore power, electrified cargo equipment, and green fuel pilots. India’s Harit Sagar guidelines and multiple port green projects show clear policy direction toward lower carbon port operations. The IMO and port associations are aligning on net zero frameworks.

- Expansion of SECU and Mega Unit Use in Rail & Sea Hubs

Larger intermodal units such as SECU remain niche but important for high-volume, specialised bulk flows. Meanwhile port projects with deepwater berths and transshipment ambitions are being built to handle ultra large vessels and heavier intermodal throughput. This supports selective growth of nonstandard large units in integrated rail-sea corridors.

- Autonomous and Robot-Friendly Handling

Automation is moving into cranes, yards and empty container depots. Governments and port authorities are tendering automated empty container yards and running semi or fully automated terminals. At present the automation is applied to equipment rather than to reengineered container bodies, but demand for robot-compatible interfaces is rising.

- Materials and Lighter Designs

Research and market interest exist for lighter panels and alternative materials, but steel remains the standard for ocean containers because of strength, cost and regulations. Expect pilot projects and lifecycle studies first, then gradual adoption if rules and cost align.

Wrapping Up

In the end, it all comes down to choosing the right box for your needs. Whether you're shipping goods across the ocean or storing equipment on-site, there's a container designed for the job. From the basic dry storage unit to specialized refrigerated and smart containers, understanding your options helps ensure your cargo is safe, secure, and transported efficiently. It’s the first and most important step in protecting what you ship and store.

Disclaimer

The content on this page is generic and shared only for informative and explanatory purposes. It is sourced from multiple online resources and may be subject to change. Kindly seek advice from an expert before making any decisions related to the discussed subject matter.